Investing in precision seed opener blades is probably one of the best things you can do to ensure successful germination and high yields from your 2023/4 crops.

Quality seed openers will open a clean, v-shaped furrow, working in tandem with gauge wheels to ensure minimal soil displacement for excellent seed-to-soil contact, minimizing the risk of air pockets that can lead to seed failures and losses due to disease.

Seed opener blades might look more or less the same, but they’re not all created equal. Wearparts seed openers are created in partnership with the renowned manufacturer Forges de Niaux in France, and have evolved in response to real feedback gathered from real farmers. This means that our seed openers have some unique features and advantages that can give you the edge.

Every seed opener blade assembly is effectively made up of the same component parts. On a row unit, there are two blades with beveled edges – these can be notched or smooth. Each blade has a central assembly or housing that contains the bearing – this allows the blade to turn. The bearing is pressed into the housing and then secured to the blade with a series of rivets. The blade is then bolted to the frame of the planter. Blades are mounted in pairs and angled so that they are touching right at the point of deepest contact in the soil. This creates a precise, v-shaped furrow. A seed then drops down into the furrow via the seed tube, which is positioned just behind the seed opener blades.

Key features of a seed opener

The seed opener has one job: to create the perfect furrow conditions for seed germination. This means it needs to cut through any surface trash, penetrating to the ideal depth and ensuring the furrow is clean, ready to receive the seed before being closed over again.

For this reason, there are three key features of any seed opener – precision, sharpness and durability.

- Precision

Precision is important during the manufacturing of the blade, both in terms of the flatness of the profile and the attachment of the bearing hub/housing. If the steel is in any way warped, or if the housing is not absolutely centered, the blade will not run true. This will result in unacceptable levels of ‘wobble’ in the blade when it runs on your planter. The resulting furrow will be uneven in width, and may be unstable. The blade will wear unevenly around the circumference, which will result in irregular furrow depth. We test all our seed opener assemblies in-house to some of the tightest runout tolerances in the industry.

- Sharpness

The sharpness of a seed opener blade is vital for ensuring the blade can cut through surface trash and achieve the optimal depth for seed placement. It’s also important where dry soil conditions are prevalent, in order to minimise the amount of downward force necessary for the blades to penetrate the soil. This reduces drag and fuel consumption costs. It’s also important that blades stay sharp as they wear down, so that the shape of the furrow stays consistent right up until the point where the blades have to be changed. The length and angle of the bevel on the blade can impact on how well a blade wears down.

- Durability

Durability and sharpness or hardness are closely linked. A harder edge on a blade will naturally be more durable; it will wear down more slowly and withstand hard or rocky soil for longer, which means less downtime spent changing blades and ultimately, a lower cost per acre. The overall durability of a seed opener blade also has an agronomic impact – a more durable blade is less likely to break or crack and can cope better with tough ground conditions so again, you spend more time planting and less time changing out damaged blades.

How are Wearparts seed openers different?

Wearparts seed opener blades have some subtle difference from the standard blade specification. These have been developed in direct response to what farmers told us they wanted in a seed opener blade, and designed to increase efficiency in the field.

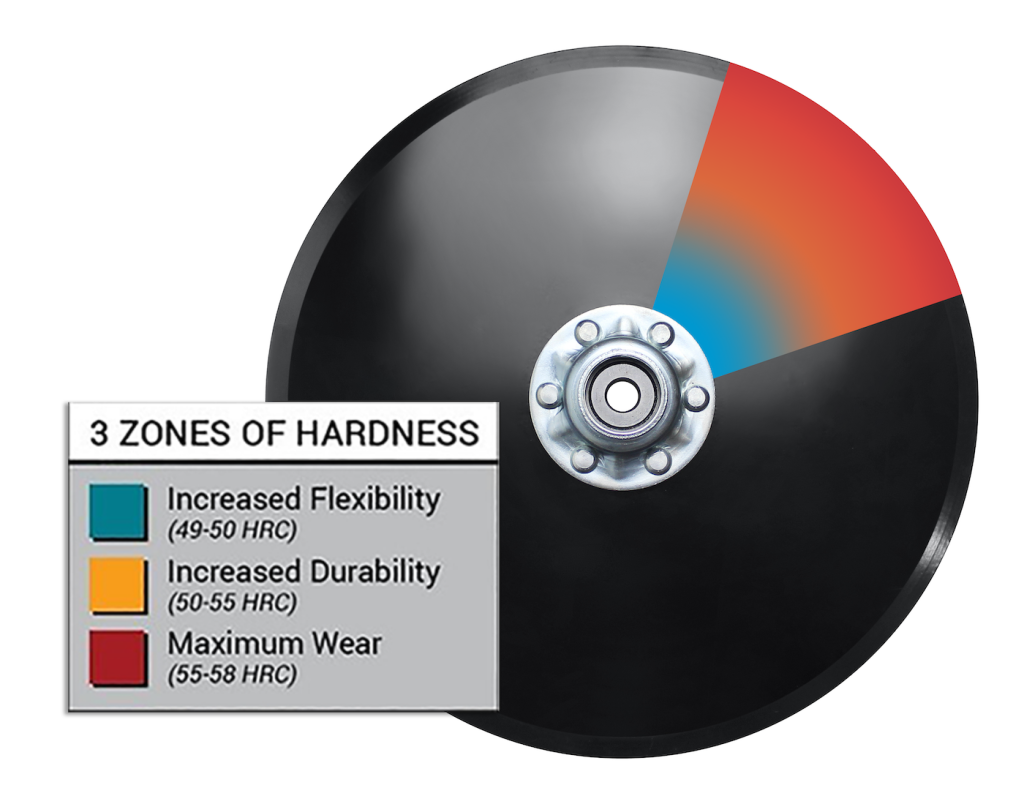

You’ll notice that images of our blades or indeed sample products at your local dealership have a distinct ‘pie slice’ illustration on the face of the blade, which hints at one of the biggest differences – the fact that our blades are heat treated to achieve a harder spec on the edge. We also offer a longer bevel, plus a larger bearing and rivets. Let’s take a look at the key benefits of each:

- Heat treated boron steel

The heat treatment process on our boron steel seed opener blades has the effect of creating variable hardness in different areas of the blade. Our blades have three zones of hardness as indicated by the ‘pie slice’ decals we apply to our sample products.

During the hardening process, extreme heat is applied to the outer edge of the boron steel blade. This causes structural changes in the carbon structures within the steel. The hardest zone is indicated by the red section of our pie slice, which is rated 55-58 HRC on the Rockwell scale and has been designed specifically to offer a longer wear life on the ground-engaging portion of the blade.

The middle part of the blade naturally also heats up during this process, but the temperatures reached are slightly lower. This zone is highlighted in orange, and is harder than non-treated steel, but still retains a degree of flexibility (50-55 HRC).

The inner zone closest to the hub is highlighted in blue. This zone does not reach high enough temperatures during the hardening process for those structural carbon changes to take place, so this area of the blade remains in its natural, flexible state (49-50 HRC). This is important because while the cutting edge is exposed to wear from the soil, the center of the blade is exposed to the highest levels of stress from the weight of the machinery and the drag of the soil, making the zone closest to the hub more prone to breakage. Retaining the flexibility here reduces this risk.

- Larger bearing and rivets

Because the hub of the blade is where the greatest force is concentrated within the seed opener assembly, we’ve developed a larger hub with larger, stronger rivets. This spreads the force over a larger surface area, reducing the risk of breakage.

We use high-quality PEER bearings for our seed openers, with the option of a split or solid inner race.

- Longer bevel

The bevel is the graduation of the blade edge from its full thickness (usually 3-4mm) to the actual cutting edge. The length of the bevel on a 15-inch blade is usually somewhere around a half inch and typically, by the time the bevel is worn halfway down, the blade has become too blunt to penetrate the soil. Our longer bevel means the blade stays sharp right up until the point where it needs to be changed and is able to maintain appropriate contact with its neighbouring blade, so you get more acres out of every pair.

To find out more about our market-leading seed opener blades, get in touch – or better still, visit your local Wearparts dealer, where you can see the difference for yourself! Find your nearest dealer here.