Planting season is just around the corner which means just about every crop farmer in the US right now will be thinking about how they can mitigate for the unknown and secure a good yield.

The truth is, you can’t predict what the weather or the market is going to do in 2023 – but there ARE things you can control, and that starts with the fundamentals of successful seed planting and germination.

Ensuring your planter is in the best condition, and selecting the right ground engaging components for your crop and soil type, are two steps every farmer can take to increase the chances of success this growing season – especially in no-till systems, where soil conditions can have a big impact on the performance of your planter.

Although digital technology has a big part to play in managing the performance of machinery these days, there’s no substitute for a hands-on approach to maintaining and adjusting your setup for the best possible results. Let’s take a look at some essential planter maintenance tasks you should be performing in advance of the planting season, and the details you should be paying attention to as the season gets underway.

General planter maintenance

Just like you wouldn’t set off on a long drive without checking your car for things like oil, water and tire pressure or treads, you’d be crazy to bring your planter out of a year-long storage and head straight to the field.

Pre-season, it’s vital to give your planter a complete once-over, checking for broken or worn components and ensuring that all moving parts are well lubricated. Key things to check include the bearings and mechanisms on row cleaners, and the bushings on the parallel arm linkage. Move the row unit up and down and side to side manually, to check if there’s too much movement that could cause inconsistent depth or seed spacing, and replace any worn parts.

You should also check for wear on the bottom of your seed tubes. Sometimes the disc opener comes into contact with the bottom of the seed tube, causing wear. This can result in inconsistent seed spacing or worst case, in seeds not being able to drop out of the seed tube at all.

Disc opener 101

Seed disc openers are arguably the most vital component of any planter because they are responsible for opening the furrow that will be the seed’s home for the next 8+ months. However, your disc openers don’t work in isolation – they rely on the frame weight of the planter itself to push them into the soil, and on the gauge and press wheels to ensure the correct depth, soil contact and eventual closure of the furrow.

Assessing soil conditions and physically checking the correct contact on your disc openers with the soil it VITAL – it’s not uncommon in dry conditions to see a planter riding up on the disc opener blades instead of on the gauge wheels, resulting in a furrow that is too shallow for the seed to access the correct moisture and nutrient levels for germination and strong growth.

Downward spring pressure may need to be increased in drier surface soil for adequate soil contact and to help bring moisture up to the seed. Pressure should be decreased after rainfall to avoid compacting soil around the seed.

Choosing the right blade

As for the seed opener itself, there are some important steps to consider when selecting a blade, and adjusting it for optimal performance on your machine.

Choosing the correct blade thickness is key for efficient planting and reduced cost per acre. Seed disc openers are generally available from 3 to 4.5mm thick, and farmers will differ in their opinion according to which is optimal. Since seed openers work in pairs, thicker blades will require more downward force to penetrate the soil. Thinner blades penetrate more easily, but lack rigidity and can be prone to warping or breaking.

Most farmers will agree that a thicker blade with a longer bevel delivers optimal performance in terms of precision and wear life. A shorter bevel – especially on a thicker blade – will result in the blades becoming blunt more quickly, which increases downtime and cost per acre. Worn beveled edges on seed opener discs also tend to let soil and residue into the furrow, which can impact on germination and ultimately on yield. A longer bevel increases wear life and ensures that blades stay sharper for longer.

Why choose Wearparts seed openers?

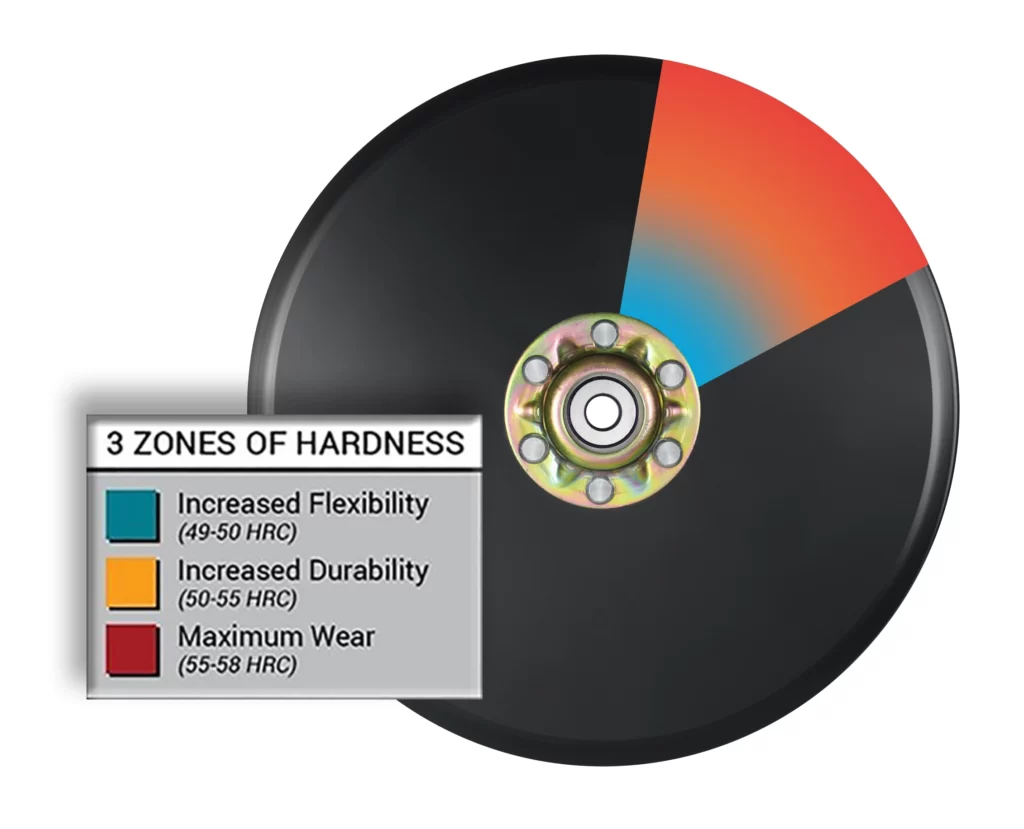

Wearparts seed opener blades have been developed in response to feedback from farmers about what they need from a seed opener, and have a number of unique features. They’re heat treated, which results in three zones of hardness – harder close to the cutting edge, and softer near the hub. This allows for greater flexibility, which facilitates better furrow closure and reduced chance of breakage. Our blades also have a larger hub, and a longer bevel for increased wear life. We test all of our seed opener assemblies in-house, and our tolerances are tighter than anything else on the market – which means we can guarantee that Wearparts seed opener assemblies will always run true.

Adjusting your Wearparts seed openers

The final thing to make sure of is that your seed disc openers are properly adjusted. Seed disc blades are designed to touch at the point of contact with the soil. In this moment, the two blades act as one to give a precise, V-shaped furrow with a clean bottom. If the blades do not touch, they’ll create a ‘W’ shaped furrow with potential to leave an air pocket around the seed when the trench is closed.

The blades should touch consistently along a certain amount of their circumference – this varies according to blade thickness, but typically 1.5-2 inches is optimal. You can check the contact distance by placing two business cards into the gap between the blades – one in front, and one in back. Push them down until they stick in the contact zone, then measure the distance between the two cards – check out this video for a how-to.

Don’t forget that even if your blades are straight and true, with sharp edges and a good contact zone, they will still wear down over time. Once a blade has lost a half inch in diameter, it’s time to replace it.

To find out more about Wearparts seed openers or to access support with planter problems, get in touch with our expert team.