If necessity is the mother of invention, it follows that when it comes to knowing what tools farmers need to get the job done, nobody knows better than farmers themselves.

Almost every piece of farm machinery we use today can trace its roots back to an implement that was designed by a guy looking to solve a problem on his own land – because when you see the problem close up, you’re best placed to develop a solution.

That’s why our customers – ag dealers and the farmers they serve – are integral to the NPD process here at Wearparts. Where OEM manufacturers are focused on the big, ‘one size fits all’ solutions, as an independent business we’ve got the agility and the grassroots knowledge to respond to the specific challenges farmers are facing in a much more intuitive way.

Inspired by experience

Take our seed opener assemblies, for example. The points of difference between OEM openers from different manufacturers are negligible – but after attending a workshop with a group of farmers, we learned that most conventional assemblies were coming up short on some key factors: hardness, bearing size, sharpness and bevel length.

So we took this information to our NPD department, and the result is our unique seed opener assembly, developed in conjunction with French company, Forges de Niaux.

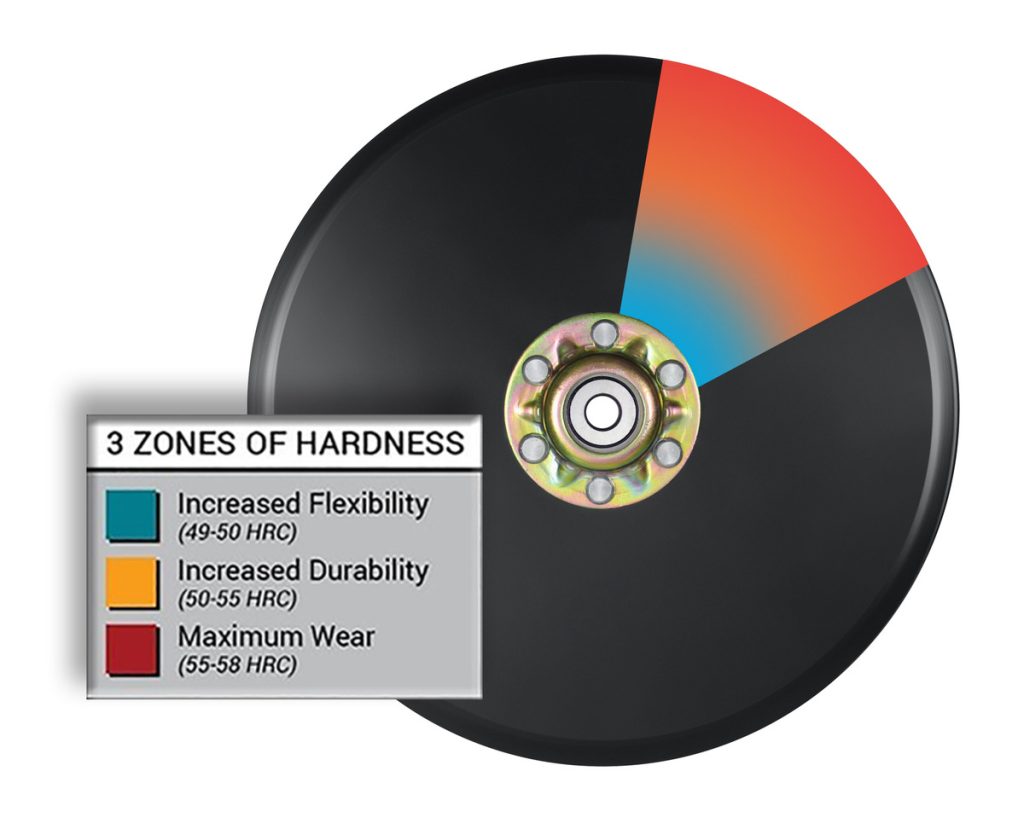

Our seed openers look the same as most – but look closer and you’ll find we’ve used an innovative heat treatment process that delivers a harder edge while retaining flexibility through the center; a longer bevel that stays sharp for longer; and a larger bearing and rivet. What this adds up to is precise performance, a longer wearlife in the field, and less costly downtime for the farmer. The differences are subtle, but in a game of fine margins, they can add up to significant uplift in a farmer’s bottom line.

Innovating for excellence

This NPD process isn’t unique to our seed opener blades. We’re always listening to farmers and thinking about ways we can improve or update our products to better meet the challenges they face, in an industry that gets more competitive every year.

At any given moment, we’ll have a number of products at various stages in our NPD process, which starts with our sales team gathering feedback from customers and culminates in the launch of a new tillage or planting tool.

For obvious reasons, we can’t develop a new product every time we get a query or some feedback from a customer – but over time, we’re able to build up a clear picture of where there is a need, based on the volume of requests for a specific product adaptation or new solution.

Our sales team are out on the ground right across the USA, listening carefully to what dealers and farmers are saying about our products and about our competitors, so once we’ve established there’s a need for something new or different, we move to the next stage of the process.

Advanced agronomics

We start by scoping out the design and product engineering parameters, as well as the commercial side. Do we need to develop something new from scratch, or can we adapt an existing product? What will it cost to make? What do we need to sell it for – and how do the costs stack up for the farmer in terms of cost per acre? Only when we’re sure that it makes agronomic sense will we proceed to actually develop the concept.

This process begins in our engineering department where, following a product request from the sales team, our designers begin by creating a CAD drawing and/or a 3D model of the product. Once they’re happy with this, they submit it to the preferred manufacturing vendor – we use vendors across Europe, North and South America and some in the Far East – for one or more prototypes to be made.

Once we receive the prototype/s at our headquarters in Gothenburg, Nebraska, we proceed to carry out fitment and field tests. The fitment tests are to ensure that the prototype/s are fit for purpose – that it fits the intended machine, and that it moves freely, interacting with any other components as it should. Once we’re confident that the product works ‘on paper’, it’s time for the real test – in the field!

Field tested, farmer trusted

We carry out field tests to establish the precision, effectiveness and wearlife of all our ground-engaging components, comparing them against data from our own similar products where available as well as comparing directly with competitor products where appropriate.

This process quickly shows up where any adjustments need to be made on the design and manufacturing side. Prototypes may travel back and forth to the manufacturer a number of times until we’re completely satisfied with the performance and specification. As a result, the time frame for our NPD process varies significantly from product to product – it can take up to a year or more to bring a product from concept to market-ready component.

Once we’re satisfied that the new product meets our stringent requirements on performance, wearlife and value for money, we place our first batch order, and recurring purchase orders thereafter. All product is received into our Nebraska HQ and quality checked before it’s stored in our warehouse ready for shipping to our nationwide dealer network.

We want your feedback

Whether you’re a farmer or an ag dealer, if you’ve got an idea for a new product or a modification to our existing range that would save you time and money, we want to hear from you! Get in touch to add your feedback to our database, and shape the future of tillage and planting with Wearparts.