As margins in US crop farming get squeezed ever tighter by rising costs and increased global competition, farming practices have become increasingly precise, especially on large-scale farms where small economies can scale up to big financial benefits.

From precision GPS planting to data-driven decisions around irrigation and nutrient application, farmers are increasingly focusing on the micro as well as the macro picture when it comes to planning ahead – and one of the key tools at their disposal is the practice of soil sampling.

But what exactly is involved in soil sampling? Why should you be doing it – and how difficult or expensive is it for the average farmer to implement? Let’s take a closer look at the theory, practice and benefits of this increasingly popular technique.

What is soil sampling?

As the same suggests, soil sampling involves taking a series of samples from a field or fields, and having them analysed either in the field or in a laboratory. Samples can be taken manually with a soil probe or even a spade, or mechanically using a soil sampling rig mounted on a truck or gator, which is more practical for large acreages and deeper samples.

The soil samples will typically be tested for three key parameters:

- Physical – to assess the texture, density and water holding capacity

- Chemical – to assess the nutrient levels

- Biological – to assess the amount of organic matter, protein and fatty acids

Why is soil sampling important?

Soil sampling is important because it gives farmers vital insights into the biggest factor influencing crop yields – the quality of their soil.

Over many years of research, we’ve confirmed what farmers already suspected simply by looking at a field of crops where some plants do better than others – which is that soil quality can vary massively not just over a distance of many acres, but from one end of a field to the other.

This knowledge enables the farmer to take a far more scientific approach to soil conditioning through tillage, the use of organic matter, or the application of synthetic fertilizers. As well as enhancing crop yields, this measured approach can reduce wasted resources or labor and associated costs, as well as having environmental benefits such as improving water quality, reducing flooding or preventing soil erosion.

What does soil sampling test for?

When you send your soil samples off to the lab, they can be tested for a wide variety of different properties that will let you know what course of action you need to take to improve the soil in that field or zone. Here’s a look at some of the key things your lab will report back on:

Here’s a list of things typically reported during the soil sampling process in the lab, along with why they are important:

- pH Level

Soil pH affects nutrient availability. Most crops thrive in slightly acidic to neutral pH (6.0-7.0). If the pH is too low or too high it can limit plant growth by affecting how well they can absorb nutrients. - Nitrogen (N)

Essential for plant growth, particularly for leaf and stem development. Insufficient nitrogen leads to poor growth and low yields, while excess nitrogen can lead to environmental issues like leaching into waterways. - Phosphorus (P)

Critical for root development and energy transfer within plants. Phosphorus deficiency can stunt growth, reduce yields, and limit the plant’s ability to produce flowers or fruit. - Potassium (K)

Vital for overall plant health, disease resistance, and drought tolerance. Potassium also helps regulate water and nutrient movement in plant cells. Deficient levels reduce crop quality and yield. - Organic Matter

Organic matter improves soil structure, water retention, and nutrient supply. Soils rich in organic matter promote healthy root development and enhance microbial activity, improving overall soil health. - Cation Exchange Capacity (CEC)

Indicates the soil’s ability to hold onto essential nutrients (such as calcium, magnesium, and potassium). A higher CEC means the soil can retain and supply more nutrients to plants. - Micronutrients (e.g., Zinc, Iron, Copper, Manganese

Though required in smaller amounts, micronutrients are crucial for various biochemical processes. Deficiencies can cause stunted growth and poor crop quality. - Soil Texture (Sand, Silt, Clay)

Soil texture influences water retention, drainage, and nutrient availability. Sandy soils drain quickly but hold fewer nutrients, while clayey soils hold water and nutrients but may have poor drainage. - Electrical Conductivity (EC)

Measures soil salinity, which can affect plant growth. High salinity levels reduce the plant’s ability to absorb water, leading to stunted growth or plant death. - Calcium (Ca) and Magnesium (Mg)

Both are essential for plant structure and development. Calcium helps build cell walls, while magnesium is a key component of chlorophyll and is vital for photosynthesis. - Soil Compaction (sometimes tested via bulk density)

High soil compaction restricts root growth and water infiltration, making it harder for plants to access nutrients and moisture.

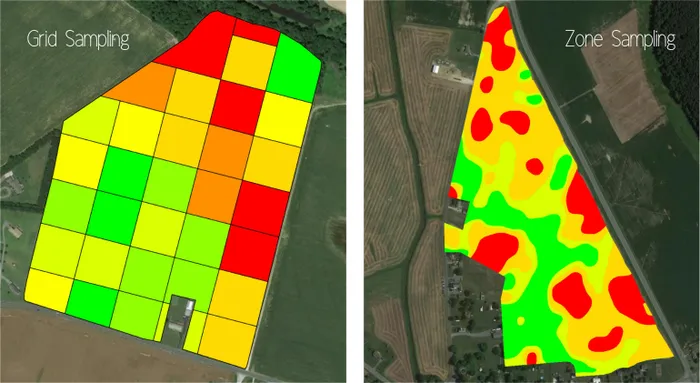

Methods of soil sampling: Grid vs Zone

There are a number of common methods for soil sampling, but the most popular are grid sampling and zone sampling. Let’s take a look at the differences and benefits of each.

Grid soil sampling

Grid sampling involves taking samples at regular intervals across the landscape of a field, using satellite or GPS to overlay a grid pattern on a map of the field. The grid size can be adjusted depending on the level of data resolution – 2.5-acre grids are commonly used, but smaller grids provide more insight (especially on non-uniform fields) and it can be useful to match grid size to spreader equipment width.

Soil samples are then collected from specified points within each grid cell, bagged up, labeled and tested.

What are the benefits of grid sampling?

Grid sampling is most useful when you have little information about the variation in nutrient levels across a field – for example, if you’re farming a new piece of land. It’s also useful in cases where topography is uniform but crop stands are irregular. A key benefit of zone sampling is that it allows you to build up a clear overview of soil quality that is relatively free from subjective biases – however, it is a time consuming and expensive method.

Zone Soil Sampling

Zone sampling involves dividing a field into zones that are uniform enough to be managed as a whole and then sampling to determine the average soil health for those zones. So for example, a part of the field that is on a slope might be one zone, while a low-lying area might be a different zone. The success of the zone sampling relies on the amount and quality of the data used to determine the zones. Layers such as soil maps, aerial photos, yield maps, topographic maps, management history and personal field experience can provide valuable information about the variation in a field.

What are the benefits of zone sampling?

Management zones are a better choice than grids when the farmer has prior knowledge of the field conditions gathered over time. Fewer samples are taken compared to grid sampling, which reduces the overall cost of lab analysis. By focusing on defined zones of similar characteristics (soil texture, topography, yield patterns), farmers can combine their own knowledge with valuable data to get better results.

| Factor | Grid Sampling | Zone sampling |

|---|---|---|

| Cost | Higher, due to more samples and lab analysis | Lower, with fewer samples per acre |

| Time and Labor | More time-intensive and labor-heavy | Faster, less labor-intensive |

| Insights Gained | Provides very detailed, site-specific data | Offers broader insights, more generalized for larger zones |

| Precision | High precision, suitable for precision agriculture | Less precise, relies on prior knowledge of field variability |

| Best For | Fields with high variability, farmers using precision agriculture tools | Fields with moderate variability, budget-conscious farmers |

When should soil sampling be carried out?

Soil sampling is typically done in the fall after the main crop has been harvested and before any tillage has been carried out. This gives ample time for a management plan to be considered and implemented before the following season’s crop is planted.

You should avoid taking soil samples during wet weather, as a high moisture content in the samples can skew the results. Soil sampling is usually carried out every 2-5 years, since it takes time for soil biology to respond to changes in management. The exception is testing nitrogen levels, which change rapidly in response to fertilizer application and can be tested annually if desired.

How can farmers respond to soil sampling results?

Once you have the results from your soil sampling tests, you should have a clear picture of what needs to be done to improve the soil in problematic areas of your farm, and also of any actions you need to take to prevent wasted resources, or to protect the environment (for example, if your soil has too much nitrogen, it could be leaching into waterways).

At Wearparts, we offer a wide range of tools that can support your resulting soil management efforts, from deep and shallow tillage tools to incorporate organic matter and break up compaction, through to fertilizer knives designed to place liquid or anhydrous nitrogen below the surface of the soil, where it can be readily accessed by young plants.

To find out more about our range of premium components, or for answers to specific questions around soil improvement techniques, get in touch.