Generally speaking, farmers fall into two camps when it comes to choosing seed openers for the upcoming planting season – the guy who sticks with what he knows because they work ‘well enough’, and the guy who’s on a never-ending quest for better.

If you won’t settle for ‘good enough’, then you’ve come to the right place – because at Wearparts we know from experience that all seed openers are not created equal.

In our conversations with farmers and ag dealers, we often hear that OEM blades, in particular, don’t live up to the hype associated with their name – common problems include a high rejection rate during preseason checks or premature wear and chipping out in the field.

Over the past decade, we’ve worked with manufacturers and farmers to deliver what we confidently believe are the best seed opener assemblies on the US market. So what makes a great seed opener – and why are Wearparts seed openers better? Let’s take a detailed look at our bestselling blades, and find out.

What makes a superior seed opener?

Premium quality blades start with premium quality steel – and our mission to address common seed opener problems experienced by US farmers started in Europe, with world-renowned French manufacturer, Forges de Niaux.

FDN’s famous ‘French disc’ has been developed based on more than 75 years of agricultural and engineering expertise, as well as real feedback from farmers, and they are known for their exacting standards when it comes to selecting the steel their disc blades are made from.

Patented heat treatment

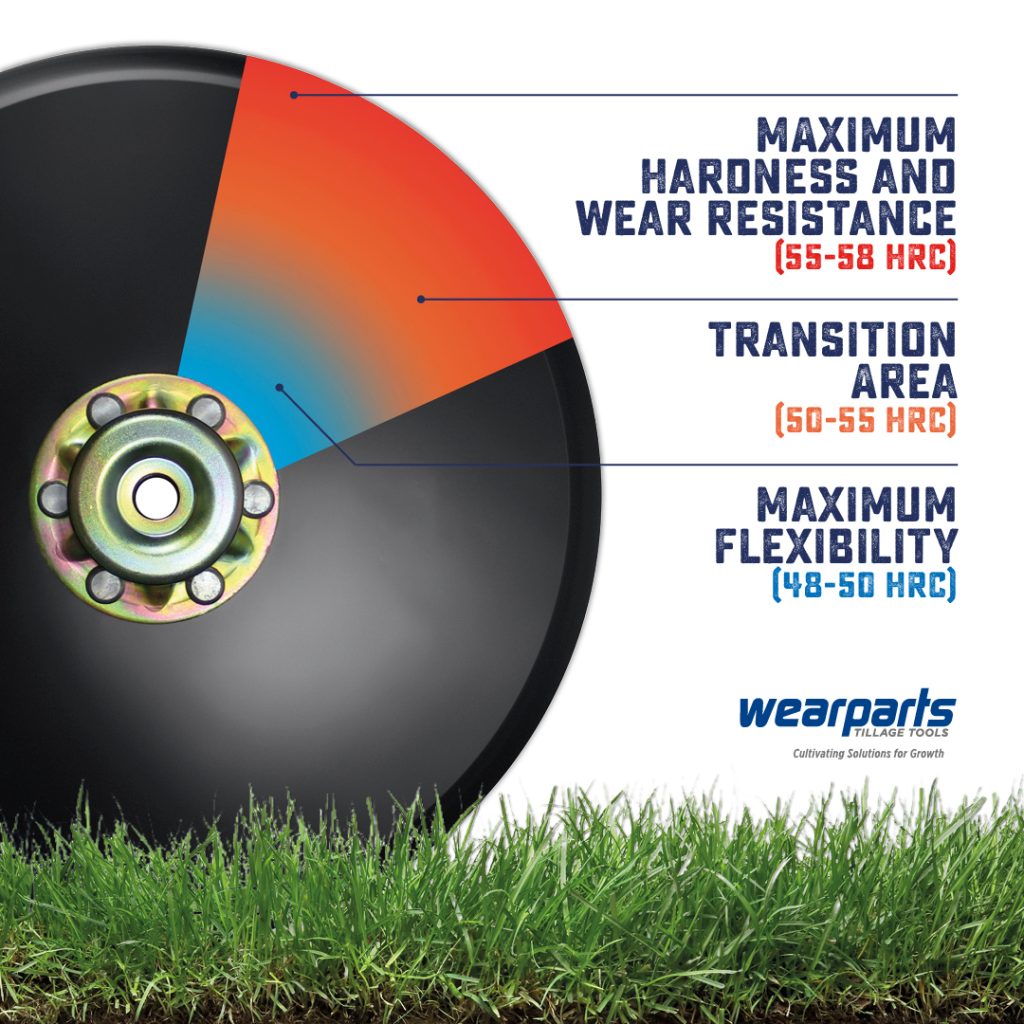

One of the key USPs of the FDN seed opener – the Niaux 200 – is the company’s patented heat treatment process, which gives the blade three defined zones of hardness/flexibility.

This breakthrough metallurgical technology came about after many years of research and testing and is the key reason Niaux blades are proven to last on average 30% longer in the field than any competing product. Here’s how it works:

- The greatest heat concentration is applied near the edge of the blade, resulting in maximum hardness and wear resistance (55-58 HRC).

- A slightly lower heat concentration is applied to the transition area on the face of the blade, resulting in a superb balance of hardness and flexibility (50-55 HRC) that enables the blade to cope with shocks and stresses without inhibiting performance.

- In the center of the blade, heat concentration is lowered to reduce hardening and retain maximum flexibility (48-50 HRC), allowing the blades to bend so they can cope with extreme axial and radial loads without fracturing.

Self-sharpening seed openers

In addition to this advanced structural integrity, each blade features a longer bevel – ¾” as opposed to the standard 5/8” found on most OEM opener discs – and unique ‘self-sharpening’ technology that promotes supremely even wear even in challenging soil conditions, allowing the blade to get sharper, not duller, as it wears down.

Durable seed opener assembly

Having answered our customers’ requests for a sharper edge and a longer bevel, we turned our attention to the seed opener assembly itself. Farmers told us they wanted a larger, more robust hub with larger rivets, and that’s what we gave them – our Maximum Duty seed opener assemblies for John Deere feature a 5mm cast housing, with heavy-duty PEER bearings and 5/16” rivets for advanced load capacity and supreme durability.

Advanced seed opener testing

The final piece of the puzzle is precision – because you can have all the features you like on a seed opener, but if it doesn’t run true, it’s not worth the steel it’s made from. Wearparts seed openers are a cut above not just because of the advanced blade technology, or the carefully designed hub assembly, but also because we hold ourselves to the very highest standards in the industry for blade tolerances, and we test 100% of our seed openers before they leave our warehouse.

Guaranteed to run true

Our Guaranteed True® promise means our seed openers have to meet radial and axial tolerances that are typically half of that permitted by OEM manufacturers.

Each blade must achieve a minimum of .050/1.27mm axial / .060/1.52mm radial tolerance, and our tests show that a significant percentage pass our tests with half of that to spare.

As a result, Wearparts blades have virtually no wobble or lope, which means rejections during preseason testing are kept to an absolute minimum, and blade shimming takes a fraction of the time – so farmers can get on with the real work of getting those seeds safely in the ground come spring.

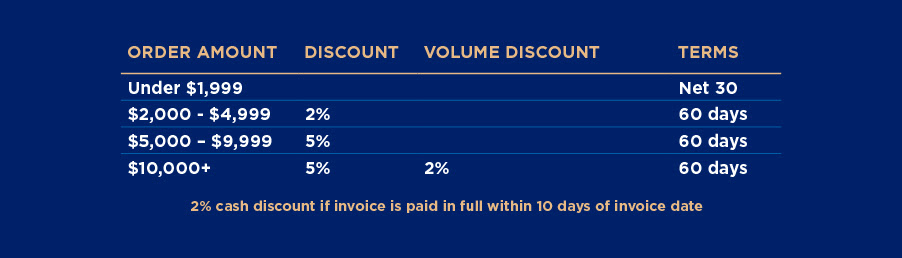

Competitively priced

Our Maximum Duty seed openers have a better specification than the John Deere OEM alternative, with a proven longer wear-life and our Guaranteed True® promise – but in terms of price, they stack up favorably, delivering even more cost-effectiveness for farmers.

What farmers say about our seed openers

Longer wear-life is what sets our seed openers apart, and this is emphasized by the feedback we get from farmers – we’ve had guys tell us they weren’t even getting one season out of their OEM openers, and now they’re getting two years from their Wearparts blades.

Watch Ottawa County farmer Darren Sanders explaining to Mark Franzen why he switched to Wearparts seed openers and the difference it’s made to his farming:

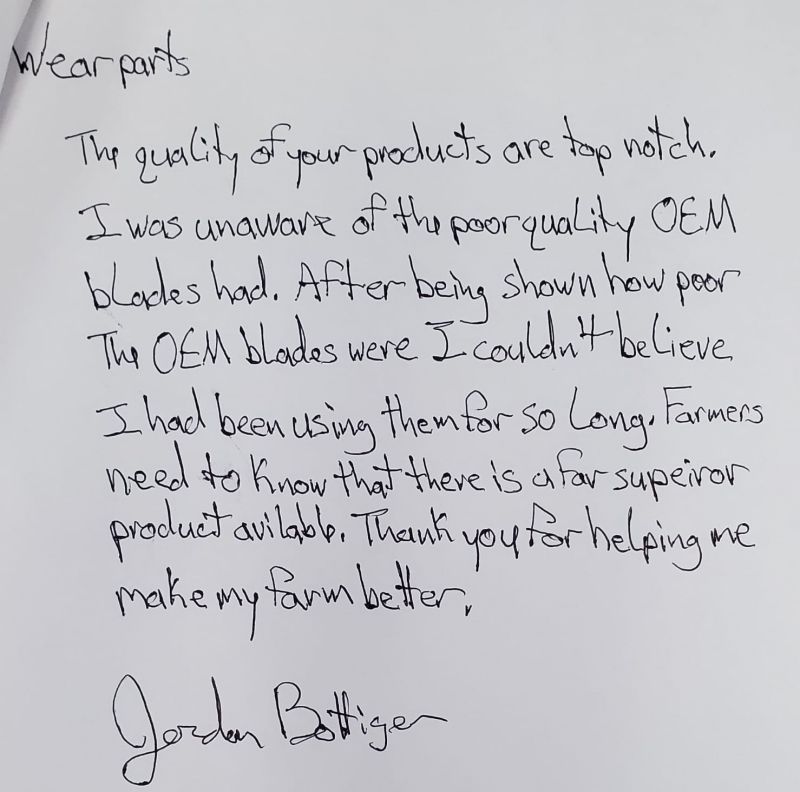

We’ve also had those risk-averse guys who always play safe with OEM tell us that their farming operations have been enhanced once they realized how much more efficient our seed openers are compared to what they’d been using for years – here’s what one farmer said: “After being shown how poor the OEM blades were, I couldn’t believe I had been using them for so long. Farmers need to know that there is a far superior product available. Thank you for helping me make my farm better.”

Need more information?

If you’re interested in learning more about Wearparts premium quality seed openers, or you’re ready to try them for yourself, find your nearest dealer from our nationwide network – or get in touch with our team for further information.