Agriculture in the USA has increasingly become an industry of fine margins. A tweak here, an innovation there – farmers must tune in to small changes in the industry and technology that can help them to squeeze that vital extra profit out of a business that is largely stretched to its limits.

But a few years back, a change to legislation triggered something of a gold rush in farming. Changes to the Farm Bill 2018 took hemp off the list of controlled substances, and opened a floodgate.

Farmers raced to plant hemp, lured by soaring demand. Many made a tidy profit in 2019, but just a year later, the bubble seemed to burst. Huge supplies of hemp lay unsold as farmers struggled to access processing facilities, while others suffered crop failure due to bad weather.

Despite this, many farmers remain interested in the possibilities of hemp as an alternative crop – but they’re understandably cautious.

Why grow hemp?

Industrially-grown hemp is an extremely versatile crop. It grows quickly, often in less than 100 days, requiring less pesticides and weedkillers than other crops, and using less water. It’s also known for its deep roots, which can help to break up compacted soil, prevent soil erosion and sequester carbon.

Hemp used to be widely grown across the US for these very reasons – even the founding father, George Washington, is known to have cultivated hemp, and an early draft of the Declaration of Independence was printed on hemp paper.

Today, demand for hemp is growing worldwide due to increased awareness of the potential health and environmental benefits. This makes hemp growing an extremely interesting prospect for farmers who may be struggling to make money from other crops.

What’s the difference between hemp and marijuana?

Industrial hemp is part of the cannabis sativa plant family, which essentially means it’s related to marijuana. But industrial hemp varieties are extremely low in the psychoactive component of the plant, called THC. The USDA specifies that agricultural hemp grown in the USA must have a THC content of less than 0.3%, or it must be destroyed.

What is hemp used for?

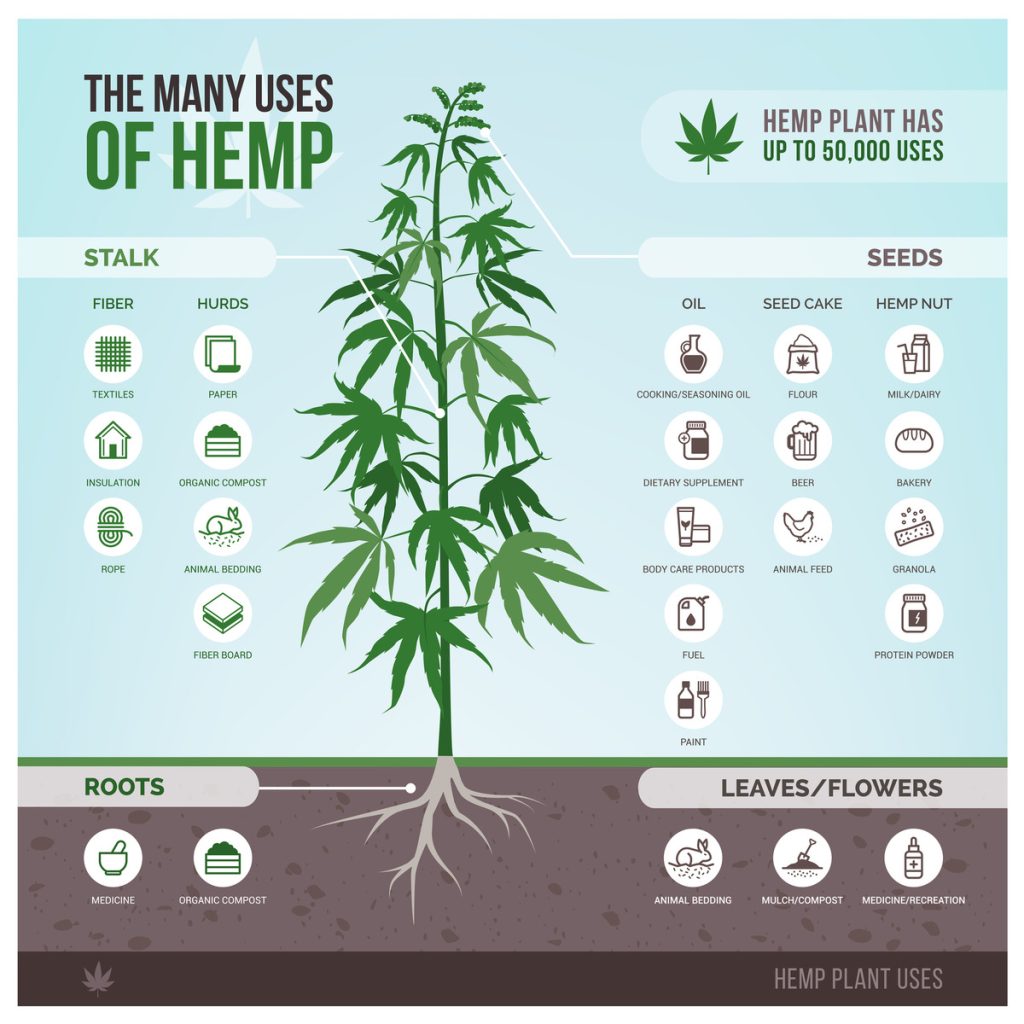

Hemp has a huge variety of uses. The majority of hemp grown in the USA is grown for its flowers, from which oil can be extracted for use in the manufacturing of CBD products. The demand for CBD oil is growing exponentially due to its health benefits and effectiveness as a treatment for a wide range of complaints, including pain, anxiety and insomnia.

Hemp can also be grown for its fibre, which has a huge range of uses. It’s an environmentally-friendly alternative that can be used to make paper, textiles, plastics, biofuels and construction materials.

Lastly, hemp can be used as food. It’s approved as a foodstuff for humans and pets in most states, but currently it cannot be fed to livestock that will enter the food chain.

Is growing hemp legal in the USA?

The 2018 Farm Bill removed hemp from the USDA’s list of controlled substances, making hemp production legal at federal level in the US. But many individual states have their own laws and regulations governing hemp cultivation, and some (like Colorado and Oregon, for example) are more welcoming to the cultivation of hemp than others (such as Idaho and South Dakota).

Before investing in hemp as a crop, it’s important to understand what guidelines your state requires you to follow. Regardless of where you want to grow hemp in the USA, you require a license to do so and you must inform the relevant authorities about exactly where and how much hemp you intend to cultivate each year.

Is it easy to grow hemp?

Once established, hemp is easy to grow. It is not vulnerable to many of the diseases and pests that can affect other conventional crops like corn, and is an extremely effective weed suppressor due to its rapid growth rate.

However, hemp does require certain conditions to grow well. It likes rich, well-drained soils with a neutral pH, so testing before planting is always advisable. Hemp can be killed by frost, so seeds should not be sown until the risk of frost has passed. Established hemp plants have deep roots that make them fairly drought tolerant, but young plants need moisture and will require irrigation for the first six weeks if the soil is dry.

Hemp is a photoperiodic plant, which means its growth is directly impacted by the amount of light it receives. The crop needs a minimum of 12 hours sunlight per day during the growing season, which means it may not be suitable for shaded fields or valleys.

In the USA, the pacific northwest has an ideal climate for growing hemp, with a mild climate and long growing season. Hemp is also widely grown in Colorado, Kentucky, Tennessee and California.

What tillage and planting tools are needed to cultivate hemp?

Farmers don’t need any specialist tillage or planting tools to cultivate hemp. Land for the cultivation of hemp should be identified well ahead of time and tested for the appropriate pH (6.5-7).

Hemp seeds germinate best in moist, well-aerated soil. Strong, rapid germination is essential if the young plants are to out-compete weeds. Good seed-to-soil contact is required so a firm, level and relatively fine seedbed should be prepared (similar to that for other forage crops) using the appropriate tillage tools.

Hemp can be sown in rows or using a grain drill. Narrow row planting may negate the use of pesticides or herbicides in organic systems, but planting density varies depending on the variety and purpose of the hemp – flowering varieties for oil extraction often being planted more densely than varieties for fiber or grain. Hemp can be successfully grown in no-till systems provided that the soil is warm and moist at planting, providing optimal conditions for rapid germination and growth of the seeds.

Hemp in crop rotations

Hemp makes an ideal crop to add to a crop rotation system. It grows rapidly and matures quickly, with a deep taproot system that reduces soil compaction and erosion, and draws nutrients to the surface. Hemp’s natural disease resistance means it can help to reduce pathogens in the soil while contributing to increased potassium and nitrate levels. Many farmers planting fall cereals after a hemp crop have reported increased yields and less dependence on herbicides.

Is hemp a financially viable crop?

Hemp has the potential to be a game changer for US farmers. Acre for acre, hemp’s value far exceeds that of corn and the global market for industrial hemp is expected to grow to $17bn by 2030. Hemp can also be used for many things besides foodstuffs, with the added benefit of being more sustainable to grow than almost any other crop (given the right conditions).

However, farmers who are early adopters of industrial hemp face significant challenges and must weigh the pros and cons carefully. Hemp does require fairly specific conditions for successful growth, and even if you get a large crop, there are still question marks – for instance, too much sunlight can cause the plants to grow ‘hot’, with a THC level over the 0.3% threshold that will result in those plants being destroyed.

Then there’s processing. Whether it’s CBD oil extraction or processing hemp fiber, there’s currently a lack of hemp processing facilities in the US. Farmers face significant costs to transport the bulky fiber to processing centers, and may face legal challenges along the way due to differing state laws on transportation. But with prospective processors nervous about investing in more facilities due to limited supplies of raw hemp, it’s a chicken-and-egg situation – one that farmers across the US will be watching with interest over the coming years.