Sowing Success: How Air Seeders Maximize Crop Yields

From the horse-drawn plow to the modern day agricultural planter, farmers throughout history have sought to make the process of planting and growing crops more efficient in order to maximize yields – and air seeders are the most recent innovation to advance that goal.

When compared to box drill systems, air seeders have the power to bring even more speed, precision and efficiency to the planting process – especially over large acreages. This means they offer an attractive proposition for farmers who are facing higher costs and reduced premiums for their product.

But if you’ve never considered using an air seeder, or even seen one up close, you might have questions. How do air seeders actually work? What’s the difference between an air seeder and a box drill? And can air seeders really make farms more productive? We’ve done some research to help you find the answers to these questions, and more.

What is an air seeder?

An air seeder is a type of planter that uses pneumatic technology to deliver seed into the ground. The seed is volumetrically metered below the seed box or tank, which allows the farmer to precisely set the amount of seed by weight or by volume that he or she wishes to distribute per area. Where box drills rely on gravity to bring the seed from the seed box, down the tube, and into the furrow, air seeders are fitted with fans that blow the seed into the seed boot for additional precision, especially when sowing small, light seeds.

Air seeder vs. box drill: Which is right for my farm?

Air seeders are very large, heavy-duty machines, capable of covering large acreages in a short amount of time. Therefore, they are typically used on larger farms where the benefits of their added precision will accumulate quickly. Because of their extremely rugged performance, air seeders are popular with farmers running no-till systems where their extra weight and durability means they can position seeds more efficiently even in tough soil conditions. Air seeders offer particular advantages when planting small seeds like wheat, canola and rapeseed where the fine, light nature of the seeds makes them difficult to plant precisely using a conventional planter. If these crops make up a large proportion of your operations – or if you are simply looking to make the overall planting process faster and more efficient, especially in no-till, then an air seeder could be for you.

What are the benefits of using an air seeder?

There are many benefits that lead farmers to switch from box drills to air seeders, particularly on larger farms or in no-till systems. Here’s a summary of the key benefits.

Speed

Air seeders have evolved to become very large units that are often more than 50ft wide. The largest air seeder in the world is the Zells Airseeder which comes in at a gigantic 214ft! Because they are so wide, air seeders are capable of covering a lot of ground in the least amount of time. They can also be combined with existing tillage implements including disc openers and fertilizer knives to complete a series of tasks in a single pass.

Precision planting

As previously mentioned, air seeders allow for volumetric metering of the seed based on a predetermined number or weight of seeds per acre. This method allows for rapid and uniform seed distribution right across the field, which means the farmer can sow large areas quickly, even in no-till systems or when using fine seed types that might otherwise be tricky to disperse evenly. Because air seeders use fans to blow the seed into the trench, they are also able to achieve more precise depth placement on small seed types, which improves germination and ultimately, yield.

Flexibility for different seed types

Air seeders are often selected by farmers for sowing small seeds, but they can actually be used for any type of seed regardless of size or shape. Volumetric metering means it’s easy to switch from planting one type of crop to another without the need for extensive adjustments to the machine, or the need to use seed-specific blades.

Suitable for no-till

Air seeders are typically large, heavy pieces of machinery, which makes them suitable for no-till operations in two ways. Firstly, the weight of the machine means that it can easily penetrate soil that has not been tilled, and still plant the seed precisely. Secondly, because air seeders are so large and so versatile, they eliminate the need for multiple passes of the same piece of land, which reduced soil compaction overall while facilitating all the soil health benefits of no-till.

Durability and ease of use

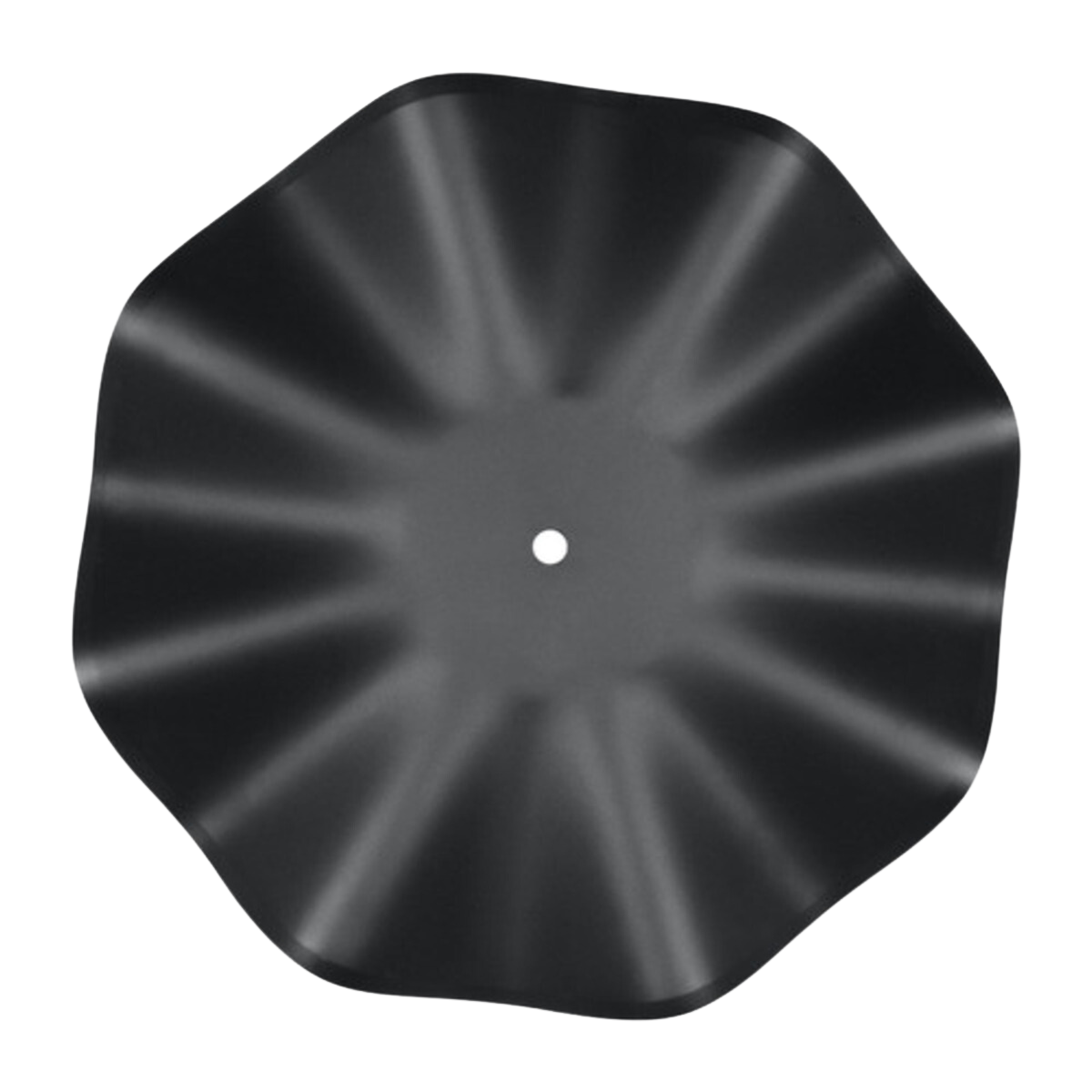

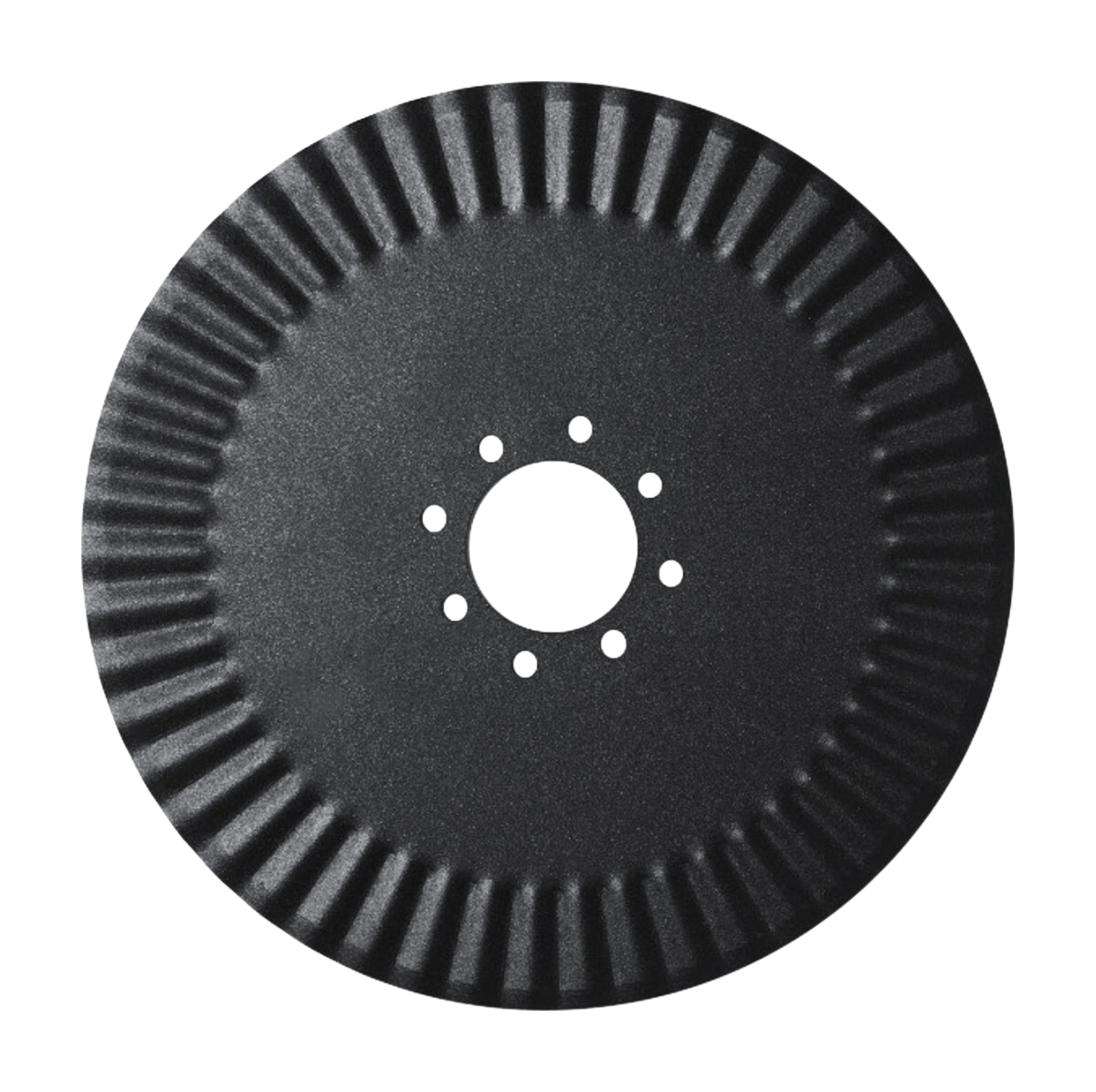

Air seeders are renowned for their ease of use and their long-term durability. Heavy duty construction on all non-ground-engaging components means that the main body of your air seeder will have a long life, with no need for advanced maintenance. The interchangeable parts – such as seed discs and hoses – are similar in design to many other planting and tillage implements and spare parts are readily available. With some simple, annual maintenance, your air seeder will give you years if not decades of reliable performance, with no need for time-consuming fine-tuning and no expensive repairs.

How do air seeders improve crop yields?

Using an air seeder for agricultural planting can increase overall crop yields in a number of ways. Firstly, air seeders reduce the amount of manpower needed to get a large crop into the ground in the first place. By covering more ground in less time, they enable farmers to plant more when conditions are favourable, and to cover larger areas without the need for additional machinery and manual labor.

Air seeders can also improve yields thanks to their precision. By enabling the farmer to adjust how much seed it planted per acre in a specific location, he can adjust for topographical and environmental variations across the farm, as well as setting the appropriate seed density for his chosen crop. This means that optimal growing conditions are created, whereby plants do no have to compete for light, water or nutrients.

What replacements parts do I need for an air seeder?

Like any piece of planting or tillage equipment, the parts of an air seeder that come into contact with the ground will wear out over time and require replacing. This includes components like seed openers, gauge wheels, seed boots and closing wheels. At Wearparts, we supply a range of replacement parts for popular air seeder models, including John Deere.

Want to find out more?

If you’re running an air seeder on your farm – or if you’re an ag dealer getting requests for specific air seeder parts – the Wearparts sales team will be happy to answer any questions you may have about our air seeder components, and help you identify the correct part number/s for your needs. Get in touch today to find out more.