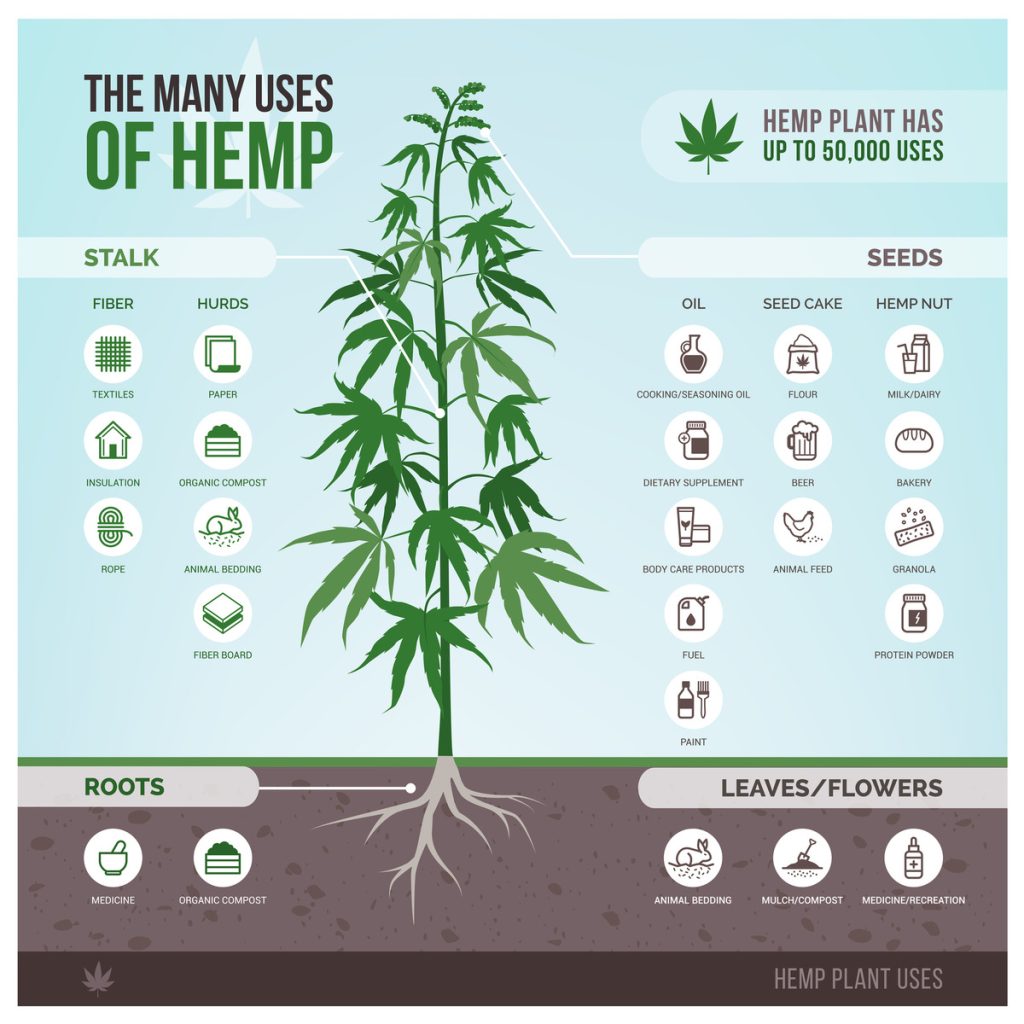

Maintaining soil fertility is a never-ending challenge for farmers, who are tasked with feeding a growing population using the same (or even less) land mass every year – and crop rotation is just one strategy farmers can deploy to keep their lands fertile.

For decades, it was thought that artificial fertilizers were an easy solution to soil degradation – after all, what could be simpler than just applying a man-made product to replace what nature lacks?

But as we’ve learned more about more about soil, it’s become clear that artificial fertilizers aren’t a cure-all for nutrient depletion, and that their overuse can actually have a negative effect on soil quality as well as the wider environment.

Crop rotation is a natural method of soil enrichment that works with the soil ecosystem to preserve structure, encourage biodiversity and fix nitrogen and other nutrients. Let’s take a look and how and why farmers do it.

What is crop rotation?

Crop rotation is a farming practice that involves systematically changing the type of crop that is grown in a particular field or location, usually from one year to the next – so instead of planting say, corn, in the same field year after year, the farmer rotates his crop by planting a different crop or group of plants in a specific sequence. The types of crops in a rotation will depend on climate, soil type and the farmer’s goals.

Why do farmers rotate their crops?

In almost every aspect of the living world, variety is a good thing. The more diversity that exists in any ecosystem, the healthier it will be – and soil is no different. By rotating their crops, farmers can change up the variables when it comes to their soil ecosystem – factors like root depth, the volume of organic matter, moisture uptake and even the presence of insects can all have beneficial effects for the soil, and therefore subsequent crop yields.

Key benefits of crop rotation

Let’s take a look at some of the benefits of crop rotation as opposed to monocropping (growing the same crop in the same place every year).

- Soil health improvement

Crop rotation is primarily used as a method of enriching the soil by rotating crops that deplete nutrients with crop that add nutrients – particularly nitrogen. Leguminous crops like clover, vetch and peas are known as ‘nitrogen fixing’ plants, which means they capture nitrogen from the air and sequester it in the soil via their roots. As well as being cheaper and more environmentally friendly than using man-made nitrogen fertilizers, it’s thought that using nature in this way makes nitrogen in the soil more readily available to subsequent crop cycles.

- Erosion prevention

Certain crops in a rotation can be used to minimize soil erosion. Plants like grasses have deep roots and underground rhizomes that bind the soil together, reducing the risk of topsoil being washed away by rain or carried away by high winds. Plants with deep, penetrating roots also help prevent soil from becoming compacted, which allows moisture to travel deeper and encourages the presence of earthworms and other organisms that work to break down organic matter and enhance the soil’s structure.

- Weed management

Crop rotations that include cover crops can aid with weed management by physically suppressing weed growth – stopping weed seeds from getting the moisture or light they need to germinate. But changing up your crops – and therefore the wider conditions in the field – can also stop any one weed species from becoming dominant. In monocropping systems, it’s common for one or two particular types of weed to thrive in the conditions that crop creates, and after several years, those weeds can become highly established and even resistant to herbicides. Changing the crop means changing the conditions, which stops unwanted species from getting a strong foothold and makes all weeds easier to control.

- Pest and disease control

Much like with weeds, specific crops are vulnerable to specific types of pests and disease. If you monocrop, the life cycles of those pests and diseases will quickly become established and can be increasingly difficult to break. Switching crops prevents these cycles from occurring, giving your crops and soil a break from pest and disease problems that could otherwise become endemic – but also attracting beneficial insects and bacteria that work to keep soil ecosystems in balance long-term.

What does a typical crop rotation look like?

Crop rotations can vary a lot depending on climate, soil conditions and the farmer’s business objectives. Here’s a very simplified example of a crop rotation and the reasons for the sequence:

Year 1: Legume Crop

Legume crops like peas and soybeans are nitrogen-fixing plants. They have a symbiotic relationship with nitrogen-fixing bacteria in their root nodules, allowing them to convert atmospheric nitrogen into a form that can be used by plants. Planting legumes in the first year of the rotation enriches the soil with nitrogen, making it available for subsequent crops without the need for synthetic fertilizers.

Year 2: Grass Crop

Corn, wheat and sorghum are all examples of grass crops. They are heavy nitrogen users and will therefore benefit from the nitrogen fixed into the soil by the legumes in year one, reducing the farmer’s dependence on synthetic fertilizers. Grass crops also have a different pest and disease profile than legumes.

Year 3: Root Crop

Root crops like potatoes, carrots and other vegetables are typically grown last in a rotation because they are less demanding on soil nutrients and also because they naturally break up the soil structure as they grow, and during harvesting. Since legumes prefer a loose soil structure, this is a useful characteristic. As with other crop groups, the pest and disease profile of root crops is different, and helps to break the cycle.

Many crop rotations are more complicated than this – particularly when cover crops are added in between cash crops or during fallow periods. The length of rotation can also vary – some farmers will grow their main cash crop for several consecutive years before going into a rotation.

What planting and tillage tools are needed for successful crop rotation?

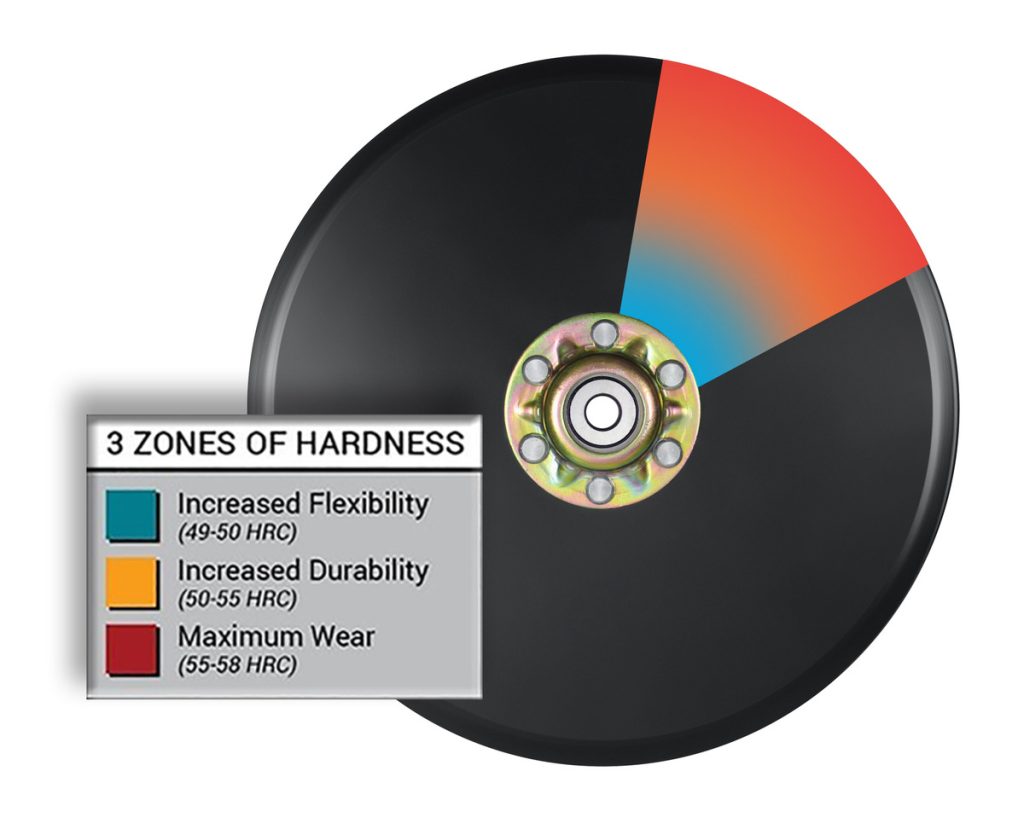

When it comes to tillage and planting in a crop rotation, efficiency is really important. The more complex your rotation is, the less you can afford downtime, so it’s important that tools like disc blades are long-wearing to avoid frequent changing, especially halfway through a busy season!

Soil compaction can be a problem in complex rotations due to the sheer number of passes required to plant and harvest multiple crops each year. Thinking about how you can reduce passes – by switching to no-till, or using multi-purpose machinery – can reduce the amount of compaction. It’s also really important to ensure your machinery and parts are well-maintained, with appropriate tire pressures and sharp blades to reduce drag.

Precision planting is also important, and you can save valuable time and energy with Guaranteed True® seed disc openers from Wearparts – we test every assembly in-house to some of the tightest wobble and lope tolerances, so you don’t have to.

To find out more about how quality parts from Wearparts can enhance your crop rotations, get in touch.