With economists predicting headwinds for agriculture in 2024 as a result of recent upward inflation and the looming threat of a global recession, it’s more important than ever for farmers to make smart choices that improve efficiency and protect profit margins.

At Wearparts, it’s always been our goal to supply aftermarket tillage and planting with enhanced precision and a longer wear life – and increasingly, farmers are recognising the benefits of investing in quality components capable of working harder for longer (spoiler alert: that doesn’t always mean the OEM).

Here’s a look at 5 ways we make sure our tillage and planting parts deliver precision, efficiency, and longevity for more profitable farming.

1. Patented Heat Treated Blades

To a non-farmer, a broken blade doesn’t sound like such a big deal – you just take the broken one off and replace it, right? But a broken seed opener or tillage blade can have fairly major implications depending on how soon you notice the breakage, how quickly you can get a replacement to the field – and what the weather is doing in the meantime.

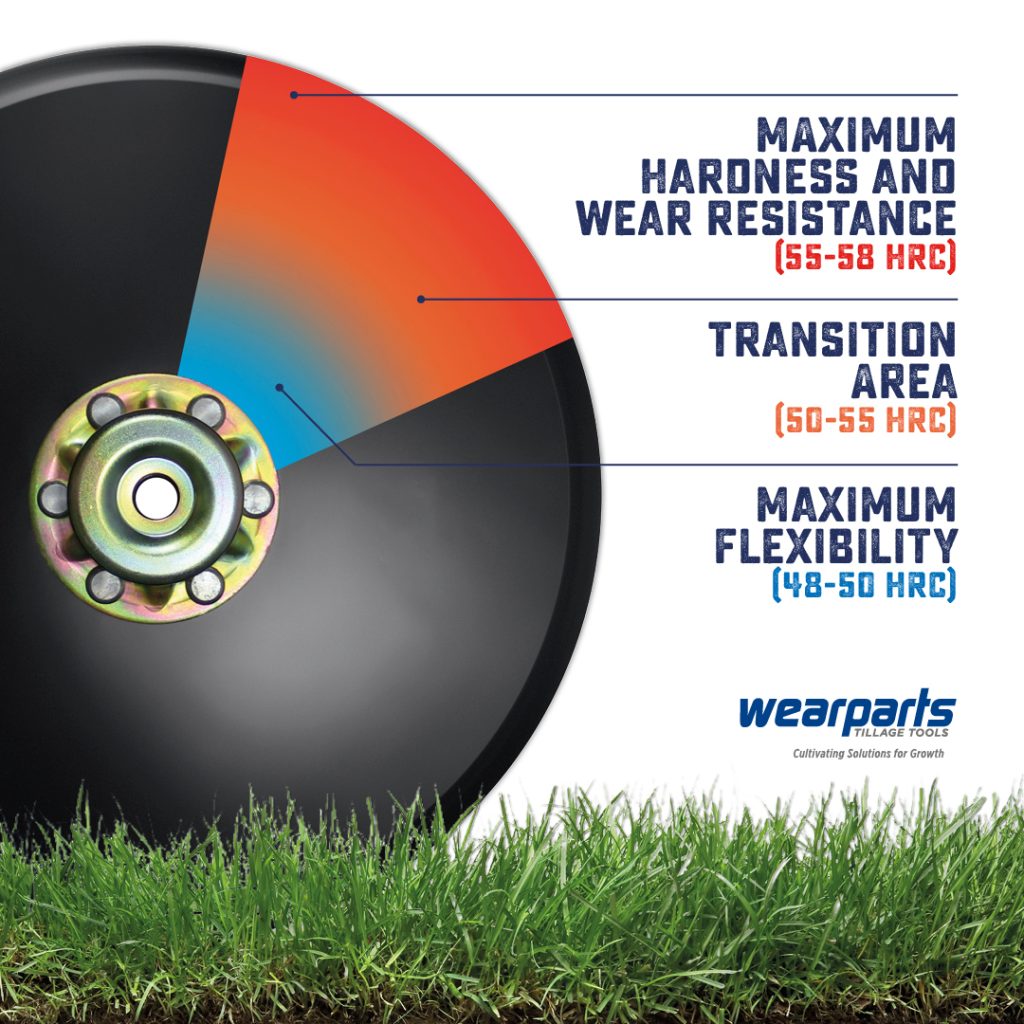

Wearparts seed openers from Forges de Niaux feature a patented heat treatment that gives each blade three different zones of hardness – they’re harder at the edge for increased durability where the blade touches the soil, but softer and more flexible towards the center of the blade so it can still flex if it hits a rock.

As a result, farmers experience a much longer wear life – often double the time of their OEM blades – with no breakages and no unpredictable downtime.

2. Custom Hardfacing

For tillage operations, you need implements with the ability to aggressively cut through compacted earth, breaking up clods, tearing through weeds and incorporating trash depending on what you’re trying to achieve.

As a result, tillage implements typically encounter heavy wear and tear along the leading edge. Our custom hardfacing service means we can offer farmers enhanced durability on tools that are pulled through the subsoil, such as sweeps and fertilizer knives.

Hardfacing adds up to 30% more material to the leading edge using a cold welding process that prevents distortion, warping, and contamination of the base metal. The resulting implement is therefore heavier and stronger and capable of completing more acres before needing to be replaced.

3. Extra Life Blades

We can’t hardface our disc blades for obvious reasons, but our Extra Life rollable blades offer similar benefits in terms of wear life. Typically, rollable blades aren’t made from boron steel because it’s not very malleable – but we’ve landed on a metallurgic composition that means our Extra Life blades have a high boron content for strength and durability, with enough malleability to facilitate the rolling process.

Rolling simply means that when the blade gets worn, it can be pressed between a set of mechanical rollers that squeeze it out to a thin, sharp edge again – restoring lost blade diameter and compressing the metal so that the cutting edge is even harder and sharper after rolling than it was before. This extends the life of the blade and gives the farmer additional cutting power.

4. Self-Sharpening Technology

All blades get dull over time – but with clever engineering, it’s possible to significantly extend the useful life of blades like seed openers while ensuring precision performance for longer.

The way a blade wears depends on how it’s made – specifically its hardness and bevel profile. Our Forges de Niaux blades are made to a unique Wearparts specification, so not only do they have that harder, heat treated edge, they also have a longer bevel – three-quarters of an inch as opposed to five-eighths.

That longer, shallower bevel means that the abrasive action of the blade turning through the soil sharpens the leading edge and ensures the pinch point remains intact for a clean, v-shaped trench. Of course, the blades will eventually wear out – but depending on soil conditions, we’ve seen our customers get double the acreage from a set of seed openers that they were previously getting from their OEM blades, and the average based on field tests is 30% longer life than the closest competitor blade.

5. Testing & Continuous Improvement

Testing isn’t something we do to our blades to physically extend their life, but it’s a hugely important part of what makes Wearparts blades stand apart from the competition.

We conduct extensive, in-house and field testing on our products in order to gather data and insights about how long they last, and how they wear. This enables us to make adjustments during the manufacturing process that can significantly improve the durability of our tillage and planting tools.

But the benefits of testing don’t stop there. Take our Guaranteed True™ promise, for example. It’s based on our commitment to testing 100% of our seed opener assemblies before they leave our warehouse. And we’re not talking about a quick check – we test to some of the strictest tolerances in the ag industry, specifically .050/1.27mm axial / .060/1.52mm radial for seed openers. The absence of wobble and lope in our blades means they’re super precise, but also that they wear more evenly, which ultimately extends their life.

Wearparts is different because we really care about farmers – as a family-run business, we know what it’s like when margins are tight so when you choose us, you’re choosing quality and integrity that’s built to make a tough job easier, and more profitable.

Find your nearest Wearparts dealer here.