First introduced in their most rudimentary form by the Romans, agricultural coulter blades have become an essential part of modern farming, and can be used in a variety of tillage and planting applications.

Choosing the correct coulter blade for your application, machinery and soil type is important for achieving consistent results and agronomic performance. But with many different types of coulter blade to choose from, it can be difficult to know which will work best. From no-till coulter blades to more aggressive styles, we’ve compiled a quick guide to coulter blades – what they are, what they do and how to navigate the different options available.

What is a coulter blade?

A coulter blade is a rolling blade that is fitted to mainly tillage implements, planters and seeders. It is a primary cutting implement, designed to fracture the soil in advance of secondary tools like plowshares, disc blades, fertilizer knives, and seed openers.

What does a coulter blade do?

Coulter blades are designed to break up and soften the soil ahead of a secondary blade. They can also chop up and bury trash left over from a previous crop, which serves to further enrich and aerate the soil. Different coulter blades have different applications. For instance, a strip-till coulter blade may be used to cut residue, where a no-till coulter blade is designed to extend the life of a seed opener blade by softening the soil and cutting residue. Coulter blades that are ran on fertilizer applicators will slice the soil ahead of the fertilizer knife.

Why do farmers use coulter blades?

Coulter blades break up heavy, compacted or very dry, crusty soil in advance of the main blades. This process delivers a number of benefits for the farmer:

- Reduces drag and prevents plugging of vertical blades

- Makes the plowing or cultivating process faster

- Enables other blades like disc blades or seed openers to penetrate to a consistent depth

- Creates a neater furrow

- Reduces overall fuel consumption and cost per acre

What are the main types of coulter blade?

The very earliest coulter blades were fixed, vertical blades but today they are typically rolling discs. Some coulter blades are flat, but most have a degree of concavity (they are shaped like a shallow dish) and are available in a range of profiles including:

Smooth coulter blades

As their name suggests, smooth coulter blades have a smooth profile with no additional blades features like notches or waves. Smooth coulter blades are thin and sharp, with the ability to effectively chop up debris – but they only offer minimal soil disturbance so are normally used for residue management in fields with good soil conditions, or for refining soil that has already been tilled using another method.

Notched coulter blades

Notched coulter blades have notches cut out of the cutting edge at regular intervals around the blade circumference. The benefit of notched blades is the amount of grip they have on the soil – this enables the blade to keep turning even in heavy soil conditions or where there is a thick layer of debris present, even at high speeds. Like smooth coulter blades, notched blades provide a narrow cutting path with minimal soil disturbance.

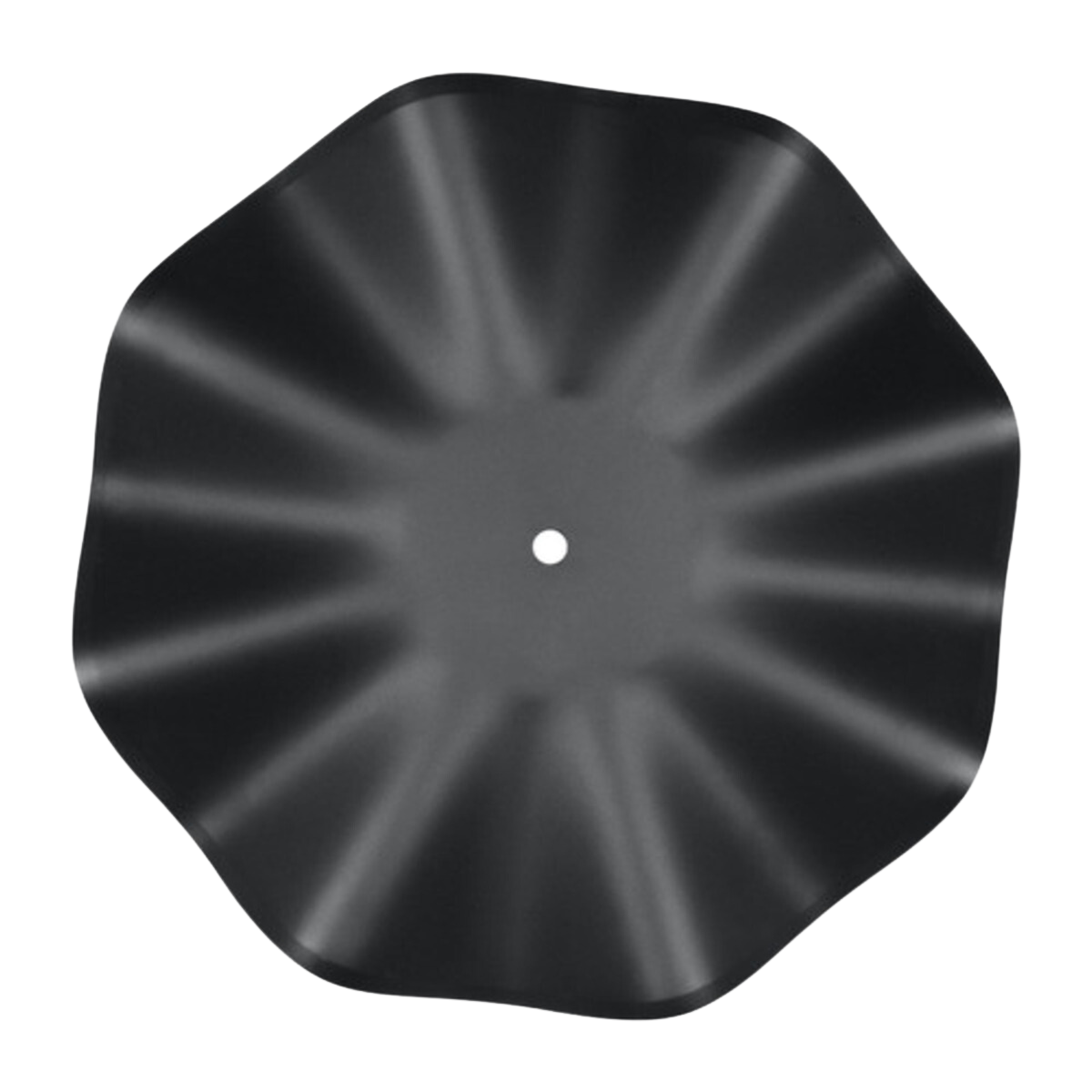

Wavy coulter blades

Wavy coulter blades have an undulating edge that resembles a pie crust. This shape means that the blade gives an aggressive action with a lot of lateral soil movement. They are designed for residue management and offer excellent tilling action in almost any soil conditions, especially at slow speeds. Wavy coulter blades come in different wave patterns or numbers – for example 8-wave or 13-wave blades. The more waves a blade has, the shallower its overall profile will be, and the narrower its cutting width – so an 8-wave blade has a wider profile, and moves more soil than a 13-wave.

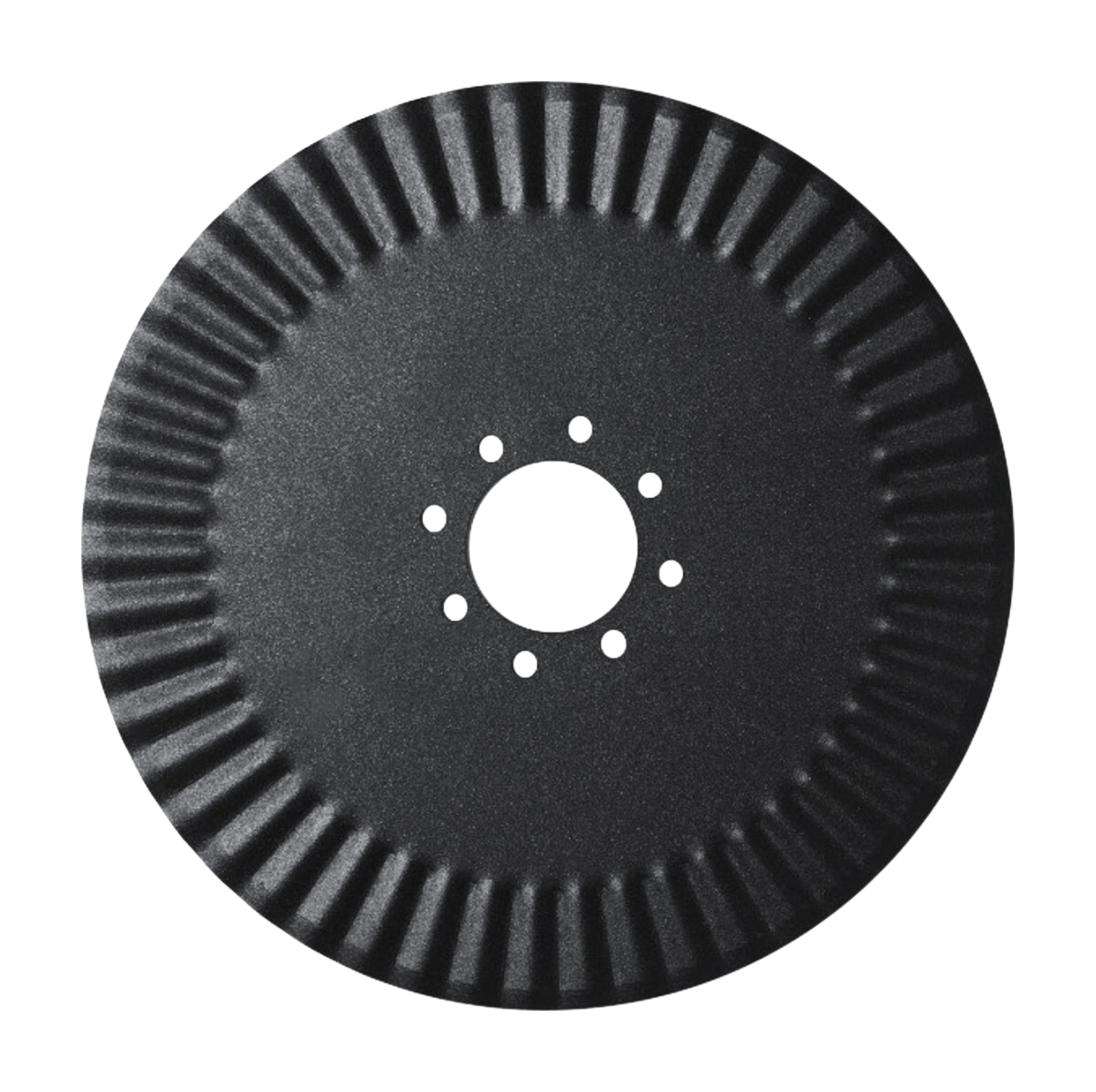

Fluted coulter blades

Fluted coulter blades are typically used when you want to achieve depth without a lot of lateral soil movement. They have a grooved pattern around the edge of the blade that increases its cutting power without adding width to the furrow, that is ideal for slicing through thick stubble or breaking up a hard soil crust. The flutes also help drive the blade and prevent it from slipping in the soil.

Directional coulter blades

Directional coulter blades are similar to wavy or fluted coulter blades, except that the waves or flutes are set at an angle to the center point of the blade. The benefit of directional coulter blades is that they offer an aggressive cutting action for residue management or hard ground, with little lateral movement of the soil. The blades run forwards, without throwing the soil sideways out of the trench. The flutes on these blades enter the soil exactly vertical, and leave when at horizontal. This helps lift the soil.

What is a no-till coulter blade?

A no-till coulter blade can be any type of coulter blade – what’s different is the way it’s used. A no-till coulter blade is there to lightly till the soil ahead of the seed opener on a planter unit, reducing the amount of wear on the seed opener and therefore prolonging its life. Most no-till farmers will opt for a less aggressive coulter – a smooth or fluted blade perhaps – for no-till applications.

What benefits do coulter blades bring to the soil?

Using coulter blades has a number of benefits for the soil, and therefore the success of a crop yield.

Weeds & residue

Firstly, they facilitate good weed control and residue management – chopping up organic matter, which stops it from growing and competing with crops, and then incorporating it back into the soil where its sequestered nitrogen will be used to feed those same crops.

Moisture absorption

Breaking up the soil – particularly in very dry climates or on heavy clay – enhances its ability to absorb moisture, and mitigates against surface runoff which can result in soil erosion and also flooding.

Soil aeration

Using coulter blades also improves soil aeration, creating tiny air pockets that allow microorganisms to flourish, and also enhancing the soil’s ability to absorb nutrients whether they are naturally occurring in the form of organic matter, or synthetic fertilizers applied by the farmer.

Optimal seed placement

Lastly, coulter blades prime the soil for optimal depth control when using other implements, particularly seed openers. By breaking up the crust and deeper soil structures, farmers can ensure their seed openers run smoothly at a uniform depth, and that good seed-to-soil contact is achieved after the furrow is closed.

What should I look for in a coulter blade?

There are a number of key things to look out for in a quality coulter blade.

Material

The first question to ask is ‘what material is the coulter blade made from?’. Coulter blades are typically made from steel, but some are heat treated or hardened, and some are made from different types of steel. At Wearparts, we use boron steel to manufacture our coulter blades because it gives the finished blades an exceptionally hard edge and long wear life, even in tough soil conditions.

Our premium Forges de Niaux blades have undergone a specialised triple heat treatment process that changes the properties of the steel along the radius of the coulter blade, making it harder at the edge and more flexible in the center. This extends the life of the blade further, and guards against breakage.

Profile

Next, look at the blade profile – is it concave, or flat? Concave or dished blades act like a scoop, moving soil sideways as they travel. The more concave the blade is, the more soil it will move. Combined with notched, flutes or waves, a dished blades can create a large amount of friable soil in a short amount of time. By contrast a flat blade will move less soil, but will have a more powerful vertical tillage action which is useful for managing residue.

Bolt pattern

When choosing an aftermarket alternative to OEM coulter blades, it’s important to check that the bolt pattern cut into the blade matches your machine. Wearparts offers in-house plasma cutting which means we can produce blades for any specification.

How to maintain coulter blades

To get the best performance from your coulter blades, it’s important that they are fitted properly and maintained throughout their lifespan.

You should always ensure that your coulter blades are fitted securely to the shanks of your plow or cultivator, and that they are set to the correct depth and angle for your application and/or soil type. Setting the angle too steep or the depth too deep can cause your blades to wear unevenly, or shorten their overall life.

Coulter blades are typically mounted on a bearing housing that contains a ball or roller bearing. The bearing is responsible for evenly distributing the loads that are exerted on the coulter blade by the soil. Therefore it’s important to make sure that bearings are in good condition, and well-greased where appropriate. If you notice a lot of noise coming from your coulter blades when they are turning, or if individual blades are wearing down unevenly, the culprit is usually a worn bearing.

Last but not least, keep an eye on your blades for signs of wear and tear. Coulter blades will naturally wear down and become dull over time – but blades that are dull will struggle to penetrate the soil, and instead of cutting trash can push residue into the furrow in a process called hairpinning. When this happens, seed to soil contact is often poor which results in lower yields.

As a rule of thumb, blades should be replaced when they have lost 1 inch of their original diameter. Some coulter blades are self-sharpening; others can be sharpened manually, provided that they have enough remaining diameter.

Want to know more?

At Wearparts, we offer a complete range of aftermarket coulter blades to fit all popular plow and cultivator brands, including Kinze, Case and Great Plains. To find out more about our product range, get in touch – or click here to locate your nearest Wearparts dealer.